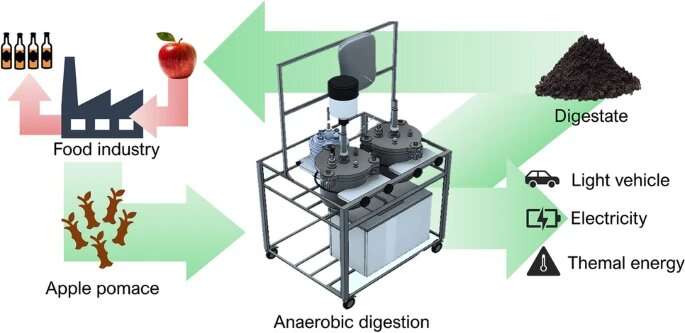

Scientists at the State University of Campinas (UNICAMP) and the Federal University of the ABC (UFABC) in São Paulo state, Brazil, have successfully produced biogas from apple pomace, the pulpy residue remaining after the fruit has been crushed to extract its juice.

An article describing the research is published in the journal Biomass Conversion and Biorefinery. The key concept is that of the circular economy, a system of closed loops designed to reduce costs, recover resources from waste, promote reuse and recycling, and maximize use of bioenergy and biomaterials.

Apples are among the most widely consumed fruits worldwide, both fresh and processed as juice, vinegar and cider, among other products. The apple processing industry throws away much of the fruit as waste.

According to the Food and Agriculture Organization of the United Nations (FAO), global apple production totaled almost 86.5 metric tons in 2020. The main producers were China (46.85%), the United States (5.38%) and Turkey (4.97%).

“Biorefining with dry anaerobic digestion produces electricity and thermal energy, reduces greenhouse gas emissions, and valorizes waste via conversion to organic fertilizer,” said Tânia Forster Carneiro, last author of the article. Carneiro earned a Ph.D. in industrial process engineering from the University of Cadiz in Spain in 2004 and is currently a lecturer in bioengineering and biotechnology at UNICAMP’s School of Food Engineering (FEA).

Anaerobic digestion, she explained, is a microbiological process involving consumption of nutrients and production of methane. Dry anaerobic digestion, with total solids in the reactor exceeding 15%, is considered an efficient method of recycling solid organic waste and far more environmentally appropriate than landfill disposal.

The results pointed to a yield of 36.61 liters of methane per kilogram (kg) of removed solids, potentially generating 1.92 kilowatt hours (kWh) of electricity and 8.63 megajoules (MJ) of heat per ton of apple pomace.

The bioenergy thus recovered could supply 19.18% of the electricity and 11.15% of the heat used to operate the anaerobic biorefining reactor designed by the researchers, who conclude that biofuels and bioelectricity can contribute to public policy, reduce fossil fuel consumption and cut the greenhouse gas emissions from organic residues.

Energy transition

The research group found the greenhouse gas emissions avoided by the biogas corresponded to 0.14 kg of carbon dioxide equivalent (CO2e) in the electricity and 0.48 kg of CO2e in the heat generated per ton of apple pomace.

“Anaerobic digestion is a stable technology and can be implemented in small to medium plants, assisting the circular economy transition and offering an added-value alternative to disposal of fruit residues as waste that benefits the entire supply chain,” Carneiro said.

The other authors of the article are Larissa Castro Ampese, William Gustavo Sganzerla and Henrique Di Domenico Ziero, Ph.D. candidates at FEA-UNICAMP; Josiel Martins Costa, currently a postdoctoral fellow at FEA-UNICAMP; and Gilberto Martins, a professor at UFABC’s School of Engineering, Modeling and Applied Social Sciences.

Carneiro and Sganzerla recently published an article on anaerobic digestion to produce methane from malting barley bagasse in the beer industry, detailing the gains in electricity and heat in terms of the balance of mass and energy in all inbound and outbound flows. The article shows that it is possible to produce 0.23 megawatt-hours of electricity for every metric ton of barley bagasse processed.