In recent years, engineers and material scientists have been trying to identify particularly promising materials for creating flexible electronics of different shapes and sizes. Ultimately, these electronics could be integrated in wearable devices (e.g., smart watches and medical devices to monitor biological signals), soft robots and other systems.

Among the many types of materials that could be used to fabricate stretchable electronics are liquid metals based on gallium alloys, which are essentially mixes of metals that include gallium. Liquid gallium alloys are intrinsically fluid and highly conductive, two advantageous properties for the creation of soft or flexible electronics.

Building three-dimensional (3D) circuits using any liquid metals, however, has so far proved challenging. This has set limits on the possible structures that can be created using liquid gallium alloys, hindering their widespread use for the creation of soft and stretchable electronic devices.

Researchers at Harbin Institute of Technology and the Chinese Academy of Sciences recently fabricated flexible electronics with 3D circuits using a liquid gallium-indium alloy. Their paper, published in Nature Electronics, identifies a gallium alloy with suitable qualities for developing flexible electronics, including a solid-liquid phase transition, mechanical strength and a good plasticity in its solid state.

“We show that a gallium–indium alloy can be used to fabricate flexible electronics with 3D circuits by exploiting the solid–liquid phase transition and plastic deformation of the liquid metal,” Guoqiang Li and his colleagues wrote in their paper.

To fabricate flexible electronics using their gallium-indium alloy, Ga10In, the researchers first cooled down a bulk sample of the alloy to low temperatures. This process allowed them to then shape the material into solid metallic wires and sheets.

“Solid but plastically deformable alloy wires are shaped into circuits at low temperatures (under 15 degrees Celsius) and encapsulated in an elastomer, before being heated above their melting temperature,” Li and his colleagues explained in their paper. “Subsequently, the supercooling effect allows the alloy to maintain a liquid state at a wide range of temperatures, including below the melting point.”

By encapsulating the prefabricated liquid metal structures in an elastomer and heating them to above 22.7 degrees Celsius, the team ensured that these structures recovered their fluidity. The process resulted in a stretchable liquid metal that conducts electricity and can thus be used to create flexible electronic components.

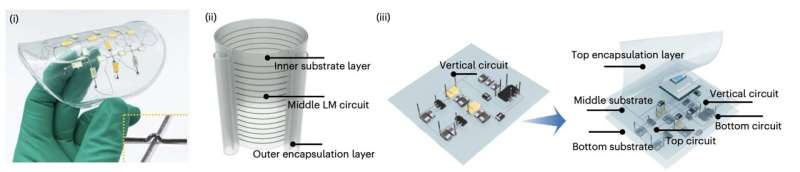

“We use the technique to fabricate high-sensitivity strain sensors, three-dimensional interconnect arches for integrating an array of light-emitting diodes (LEDs), and a three-dimensional wearable sensor and multilayer flexible circuit board for monitoring finger motion,” the researchers wrote in their paper.

In initial tests, the alloy structures created by Li and his colleagues have proved to be very advantageous for the development of flexible electronics. To demonstrate their potential applications in electronics, the team used these structures to create various electronics, including a strain sensor, interconnects for the integration of LEDs and an electronic system to monitor finger movements.

In the future, the new proposed strategy to create gallium-indium alloy-based flexible electronics could be used to fabricate similar liquid metal structures based on other alloys and materials. In addition, the alloy structures created by Li and his colleagues could soon be used to fabricate stretchable electronics, including components for wearable devices and soft robotic systems.