Electric vehicle makers have been leaning on longer range EV batteries for an edge over the competition, but range can only get you so far. Sustainable manufacturing is also gaining traction, as automakers seek to cut the long tail of energy, water, and waste dragging behind their zero emission rides.

Sustainable Manufacturing & The EV Batteries Of The Future

There is plenty of room for improvement in EV battery manufacturing, sustainably speaking. The US firm 6K provides a good illustration. The Massachusetts startup just won $50 million in funding from the Biden administration to manufacture more sustainable EV batteries domestically, deploying a proprietary high tech process it calls UniMelt®.

The federal dollars will go towards the construction of a $107 million manufacturing plant to be located somewhere in the southeastern US. The aim is to demonstrate that the US energy storage industry can leave overseas competitors behind in the dust, and produce EV batteries that cost less, perform just as well if not better, and leave behind a smaller manufacturing footprint for energy, water, and waste.

The manufacturing model adopted by 6K does not involve the need to invent brand new battery architecture. For example, its new facility can work with NMC 811 lithium-ion EV batteries, referring to the now-familiar nickel-manganese-cobalt cathode formula.

NMC sparked much talk around EV battery circles a couple of years ago, when manufacturers like SK Innovation and LG Chem began tweaking the standard formula to include more nickel. As explained by Research Interfaces, NMC 811 was “meant to be the next-generation cathode – ‘better and cheaper’, pushing electric vehicles beyond a 500 km (~300 mi) driving range and soon to price parity with the internal combustion engine.”

According to 6K, its new UniMelt process can produce the latest generation of NMC 811 batteries while generating 70% less greenhouse gases than conventional battery manufacturing. 6K also states that its processes only uses 10% of the water and 30% of the energy used in conventional methods.

The All-Important Domestic Supply Chain

Concerns have been swirling around the availability of lithium for EV batteries. The US domestic lithium industry has yet to gather speed (more on that in a second), but manufacturers like 6K are not waiting for the grass to grow under their feet. They are counting on lithium mined from spent EV batteries and other end-of-life energy storage devices.

“6K will demonstrate the ability to leverage feedstock sources domestically, freeing the US from its current dependency on conflict nations. This will be accomplished first by upcycling recycled materials sourced from end- of-life batteries followed by the digestion of 6K’s own metals,” 6K states.

The company also points out that responsible sourcing is part and parcel of sustainable manufacturing. In addition to avoiding materials from conflict zones, that means adhering to the Biden administration’s goals for equity and environmental justice.

“Over time, the project will create up to 150 well-paying jobs and through education, recruitment, training, and retention initiatives, it is anticipated that at least 40% of the employees will come from disadvantaged communities and that the workforce will reflect the diversity of the community,” 6K states.

How Does It Work?

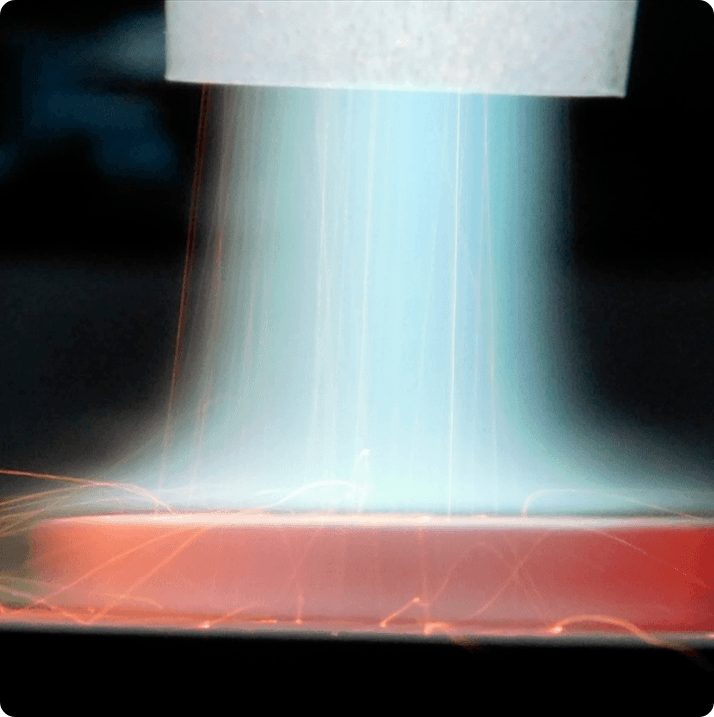

You might be able to DIY your own UniMelt-er at home if you have a microwave oven and a few other tools at your disposal suitable for pushing the boundaries of plasma chemistry, but keep in mind that you’ll need to reach a temperature of 6,000 degrees Fahrenheit. UniMelt is a production-scale, high efficiency, high throughput microwave plasma process.

“A combination of high heat, highly reactive ions, and designed chemistries create the perfect environment to collapse processes into previously unattainable periods of time,” 6K explains.

“For additive manufacturing the UniMelt process precisely spheroidizes metal powders while controlling the chemistry and porosity of the final product,” 6K notes. “For battery material, the same sustainable process is used to synthesize chemical elements and control particle size and microstructure to produce advanced battery material at a fraction of the time and cost as conventional processes.”

Shorter version: Conventional production processes involve multiple steps and different batches that suck up time and energy. Batch-type methods are also vulnerable to contamination and loss at various stages.

6K states that its microwave plasma process is a single, continuous flow operation that takes about 2 seconds, or 1/100,000th the time of today’s conventional, batch-based production technologies.

More EV Batteries For The US Southeast

So far, 6K has been mum on the exact location of its new plant, but the idea of situating a sustainable manufacturing facility for EV batteries in the southeastern US may seem a bit counterintuitive at first glance, mainly because the region as a whole has been lagging behind other states in renewable energy capacity.

UniMelt or not, 6K will have some ‘splaining to do if its new manufacturing facility for more sustainable EV batteries runs on natural gas or coal power.

Part of the problem for renewable energy developers in the southeast is a technology challenge, as wind speeds across the region are less than optimal for harvesting inland wind energy with conventional turbines. The US Department of Energy has been trying to pick that apart with support for taller wind turbine towers and longer turbine blades.

The offshore wind industry encounters a similar wind speed obstacle in the Gulf of Mexico, though the emergence of green hydrogen and green ammonia have helped improve the economic conditions for exploiting offshore wind resources there.

The Atlantic coast is a different story altogether. Political fortunes have been the main obstacle among Atlantic coast states since 2010, when South Carolina, Georgia and Florida all declined to join a new multi-state effort aimed at coordinating and accelerating offshore wind development along the Atlantic.

Solar Power To The Rescue

The southeast’s record on solar energy is mixed, but looking brighter. Georgia and Florida are currently among the top 10 states in installed solar capacity, as are the nearby states of Virginia and North Carolina. South Carolina is also catching up and currently owns the #14 slot.

Other southeast states are much farther down in the solar pecking order, including Alabama (#31), Tennessee (#28), Louisiana (#38), and Mississippi (#37), with Kentucky bringing up the rear at #46.

Kentucky might not remain a regional laggard for long. Last year, GM engineered a new solar power deal for its Corvette factory in the Bluegrass State. The Tennessee Valley Authority is lending an assist, as part of its pivot into renewable energy. A movement is also afoot to convert spent coal mines in the region for solar arrays and energy storage.

Ford is another automaker seeking more solar power for EV batteries and other manufacturing facilities in the southeast. Wherever 6K ends up, the prospects for a solar-powered manufacturing plant look a lot better now than they did just a few years ago.