To reduce carbon emissions and still meet the growing demands of the electronics industry, scientists will need to develop alternative battery technologies that are more durable, sustainable, and can store more energy. In recent years, they have thus been trying to develop alternative battery technologies using different material combinations.

Among the battery technologies that have proved to be most promising so far are lithium-sulfur (Li-S) batteries, which contain sulfur cathodes and lithium-metal anodes. These batteries could overcome some of the limitations associated with the conversion reactions in lithium-ion batteries (LiBs), ultimately achieving higher energy densities.

Despite their possible advantages, many Li-S battery designs introduced so far have not achieved the desired results. One reason for this is that the sulfur in the batteries needs to be loaded onto a conducting host, which is typically based on materials that were poorly wetted by electrolytes (e.g., most carbons). This impairs the diffusion of lithium ions in the batteries, reducing their overall capacity and performance.

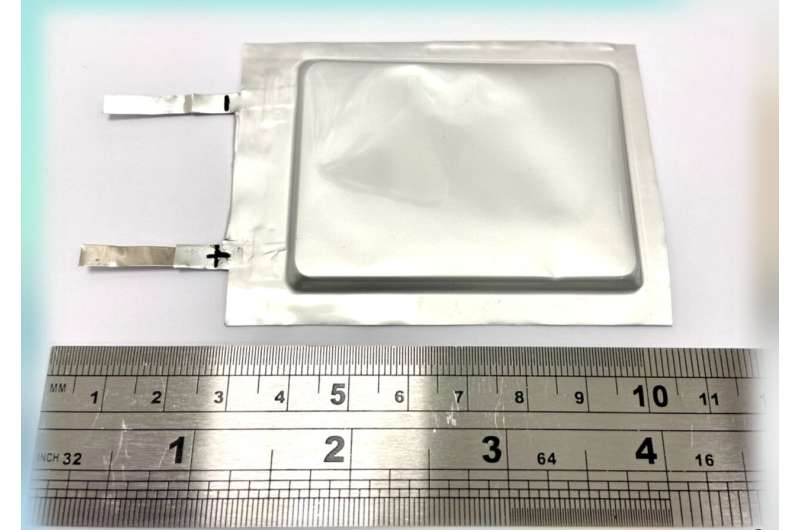

Researchers at University of Cambridge and The Faraday Institution have recently developed highly performing Li-S batteries using nanosheets of lithiated metallic 1T phase molybdenum disulfide (LixMoS2). Their design, outlined in a paper published in Nature Energy, offers great promise for the creation of next-generation battery solutions that can store more energy.

“Our recent paper is about a new material for Li-S batteries that can lead to superior energy densities,” Zhuangnan Li, one of the researchers who carried out the study, told Tech Xplore. “It is based on the metallic phase of two-dimensional material, which our research group has been working on for more than 10 years.”

The battery design introduced by Li and his colleagues build on the previous efforts by researchers at University of Cambridge. More specifically, the team has developed highly promising electrodes based on LixMoS2 nanosheets to create Li-S batteries that have numerous advantageous properties and characteristics.

“The key point of our design was to use minimum amount of electrolyte while keeping battery operation normal,” Li explained. “This requires the sulfur host material to possess properties such as high electrical conductivity, density, wettability, polarity for adsorption, and catalytically activity.”

The researchers found that their lithiated nanosheets significantly improved the absorption of lithium polysulfides, while also enhancing the transport of lithium ions, accelerating electrochemical reactions and improving electrocatalytic activity, which supports the conversion of polysulfides in Li-S batteries. Combined, these advantages resulted in remarkable energy densities of 441 Wh kg−1 and 735 Wh l−1, allowing the batteries to retain 85.2% of their capacity after 200 operating cycles.

“The high-energy and long-life Li-S batteries demonstrated in this work have great potential for the creation of next-generation of energy storage devices,” Li added. “We now plan to provide more foundational knowledge and its translation into commercially feasible battery technology.”

In initial trials, the new Li-S battery design introduced by this team of researchers achieved highly promising results, suggesting that it could help to achieve better performances and higher energy densities. Li and colleagues are now conducting further evaluations and exploring their technology’s possible commercialization.